Cold rolled coil

Description

Product Introduction

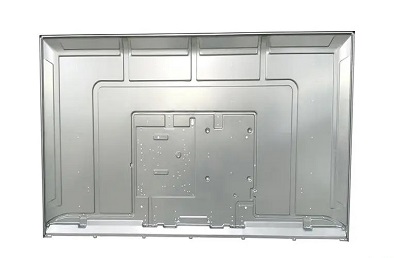

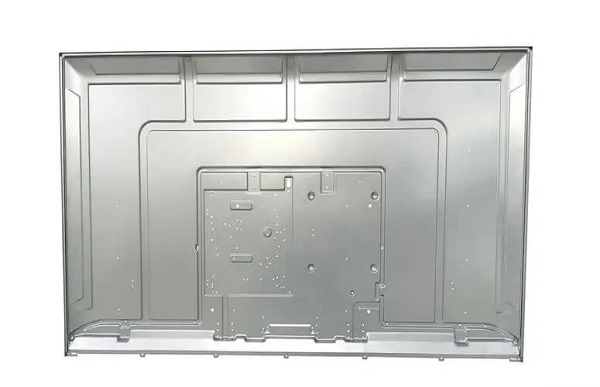

Cold rolled coil production process is rolled at normal temperature and will not be oxidized, compared with hot rolled coil, cold rolled coil surface quality, appearance, dimensional accuracy are significantly better than hot rolled coil, widely used in automobile, household appliances, hardware, aviation, industrial equipment and construction industries. In addition, the cold rolled steel coil is also used as the substrate for deep processing, becoming a high value-added product. Such as electric galvanized, hot dip galvanized, zinc alloy and pre-painted steel and so on.

Product Features

-

01

Compared to hot rolled plate, cold rolled plate surface is smoother,hot rolled surface with oxide and rough;

-

02

The precision of cold rolled sheet is higher, and the thickness tolerance can be controlled 0.01mm-0.03mm;

-

03

The mechanical properties of the cold rolled sheet can be adjusted according to customer demand , such as: tensile strength and yield strength;

-

04

Thinner thickness, cold rolled sheet can be rolled to 0.1mm;

-

05

The cold rolled sheet is generally used for high precision and surface smoothness requirements of the product;

Brand parameter information

CN

CN AR

AR PT

PT RU

RU