Aluminum zinc sheet coil

Description

Product Introduction

aluminum zinc steel sheet surface is a unique smooth, flat and gorgeous star flower, the primary color is silver white, beautiful appearance. Aluminum zinc steel sheet is divided into anti-fingerprint surface, chromated surface and oiled surface. Aluminum-zinc with anti-fingerprint is to prevent the aluminum-zinc sheet from leaving processing marks in the process of processing, the surface of the product is coated with a layer of special thin fingerprint resistance protective film, which can also improve the corrosion resistance of aluminum-zinc steel sheet. Chromated aluminized zinc sheet is to reduce the white rust produced under wet conditions, and a chromated protective film is coated on the surface of aluminized zinc coated products.The purpose of oiling aluminized zinc sheet is also to prevent the product from getting wet and white rust, but because the antirust oil is very easy to volatilize or be erased, it can only play a role before use. Customers can choose different surface treatment aluminum zinc steel sheet according to their own use.

Product Features

-

01

Corrosion resistance: The corrosion resistance of aluminum zinc steel plate is mainly from the protective function of aluminum. When the zinc is damaged by cutting, scraping, and friction between the zinc layers, the aluminum forms an insoluble dense layer of alumina, preventing further corrosion of the sheet.

-

02

Heat resistance: aluminum zinc alloy steel sheet has excellent heat resistance, can withstand more than 300 degrees Celsius high temperature, suitable for oven, lighting electrical appliances etc.

-

03

Thermal reflectivity: aluminized zinc steel sheet has high thermal reflectivity, suitable for roofing material and insulation material.

-

04

Economy: Because the density of 55%AL-Zn is less than that of Zn, the area of aluminized zinc steel sheet is larger than that of galvanized steel plate under the condition of the same weight and the same thickness of the coating.

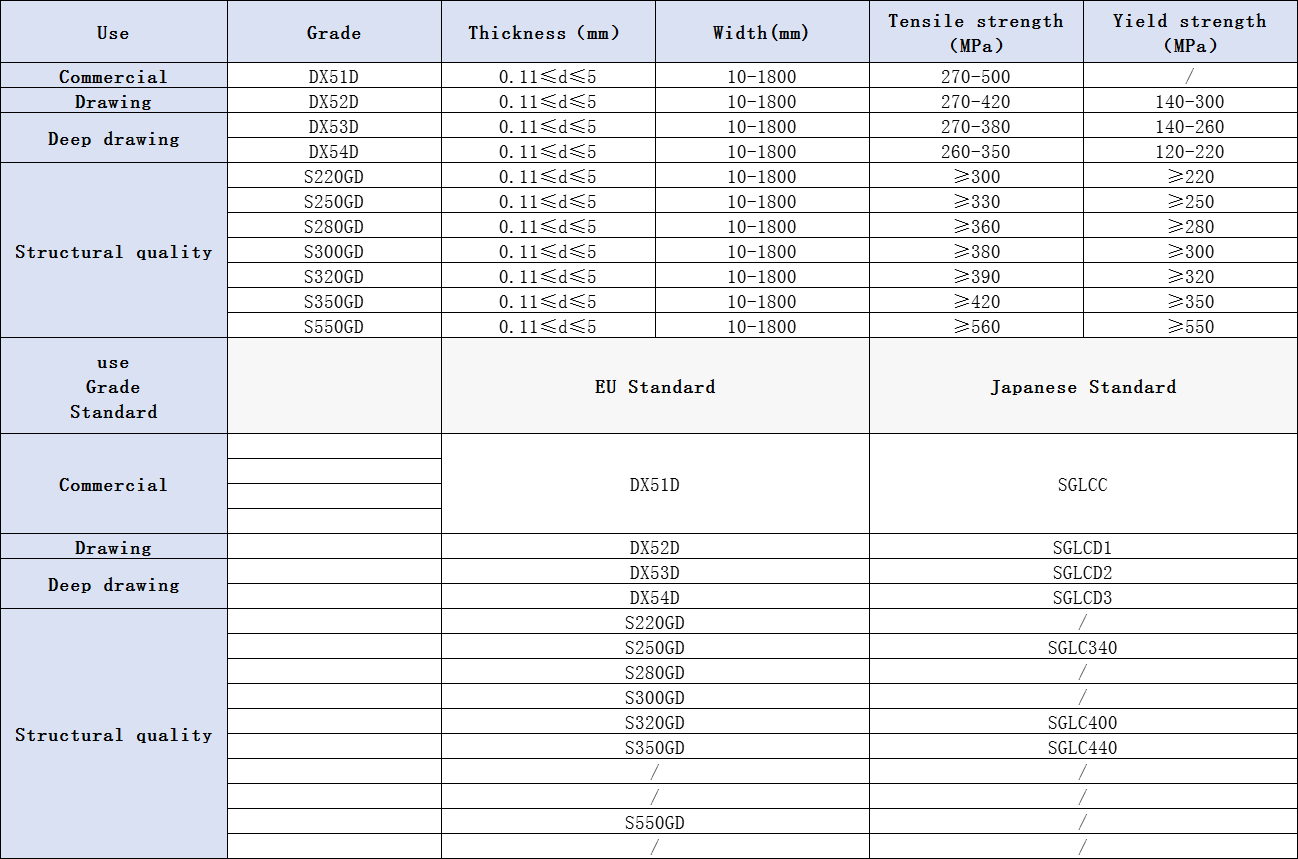

Brand parameter information

CN

CN AR

AR PT

PT RU

RU